A team of researchers from Northwestern University has developed a “carbon-negative” artificial sand that could replace conventional sand in concrete while storing CO2.

The research team, led by civil engineer Alessandro Rotta Loria, found a way to “grow” sand by injecting CO2 and electricity into seawater. The material was developed in collaboration with Cemex, a leading global cement manufacturer.

Typically, sand dredging damages ecosystems by eroding riverbeds and destroying habitats for aquatic life. Sand dredging also comes with a hefty carbon footprint, with mining and transport linked to high emissions across the construction supply chain.

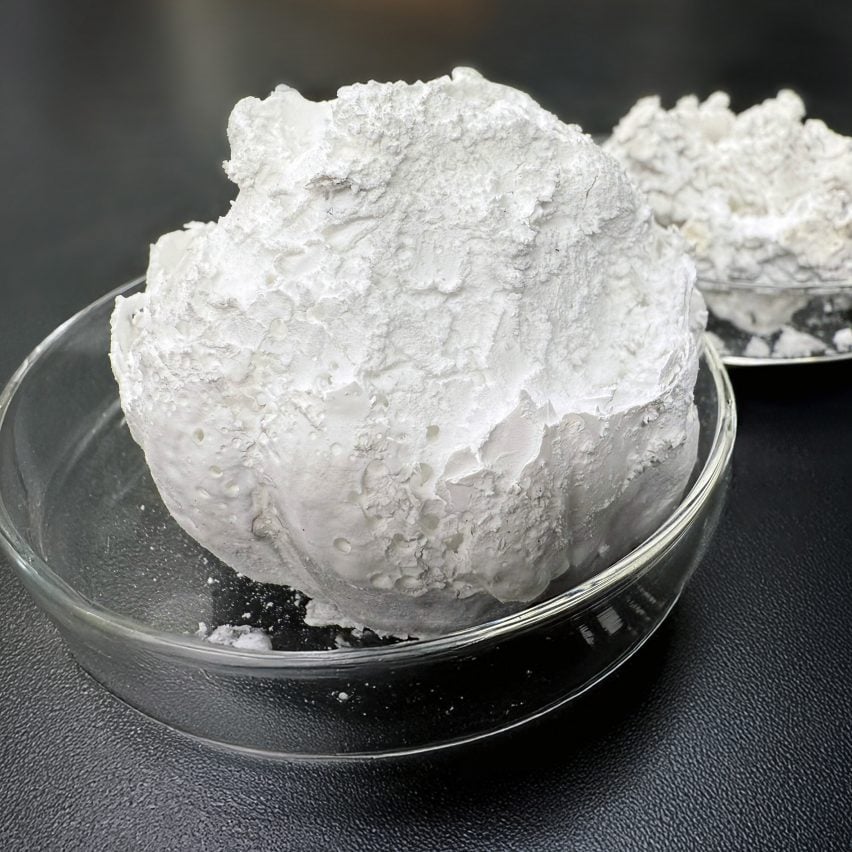

A seashell-like material

Loria said that his material is “comparable” to regular sand in terms of structural integrity and could prevent a “carbon negative” alternative when put into practice.

The process builds on breakthroughs made decades earlier, which were never brought to scale.

In the late 1980s, researchers discovered that if an electrical current is applied to seawater, naturally occurring calcium and magnesium ions can turn into solid minerals. This is known as mineral electrodeposition.

The idea was informed by the way marine organisms form shells and skeletons, but instead of using the animals’ metabolic energy, scientists used electricity.

However, Rotta Loria said it never took off. “The precipitation is instantaneous, but growth was too slow to meet construction demands,” he told Dezeen.

On any given day, a fraction of CO2 from the atmosphere dissolves in seawater and becomes a part of the liquid.

This CO2, combined with the ions that already exist in seawater, is the reason why clams or oysters can grow their shells. But according to Loria, to make enough “sand” to replace traditional sand in cement, we would need a lot more CO2.

To speed up the process – and therefore increase the material’s production rate – Rotta Loria’s team injected CO2 into the electrically charged seawater.

In a lab, with small electrodes and a small electrochemical cell, they were able to grow a sphere 9 centimetres in diameter over the course of 30 days. That is the equivalent of 0.3 centimetres per day, but Rotta Loria anticipates a higher production rate once the setup is optimised.

Circular approach to Co2 management

During the experiment, Rotta Loria used a gas concentrate that contained 99.9 per cent of CO2. He said the process could work with any kind of CO2 from a variety of sources, but the higher the concentration, the faster the production rate.

CO2 could be captured at the source from a cement plant, injected into electrochemical reactors built nearby, and turned into a sustainable construction material.”We are particularly excited because what it does is creates a circular approach to CO2 management,” Rotta Loria said.

The researchers are still working on optimising the process and lowering associated costs, but Rotta Loria estimates they will have a viable product within a year.

For years, those concerned with the built environment have been pointing to the high-carbon costs of concrete.

Gestures have been made towards reducing these climate impacts, including a series of working definitions for low-carbon concrete pitched at COP29.

Other scientific approaches to making concrete more sustainable include research at the University of Colorado that uses algae in its production.

Photography courtesy of Northwestern University.

The post Researchers develop artificial sand for concrete that can sequester CO2 appeared first on Dezeen.